Local entrepreneur, Larry Stearns, bought his first 3D printer in 2016 to help cut product development costs. The concept grew into a business of its own: Medal Technologies (MT). The company offers start-to-finish consultations and services to local industries and entrepreneurs.

Many of the company’s projects come in from other businesses, and referrals. “One customer came to us with a pet product idea after being referred from a patent attorney,” Stearns explained. He and his team are happy to guide you along the way, even if you walk in with a hand-drawn idea. That initial sketch is studied to ensure manufacturability, or a sketch is created using the most efficient process. It is then transformed into a computer-aided design, which serves as the printer’s blueprint. If you’re lost where to go after obtaining the 3D printed prototype, MT can connect you with their network of patent attorneys, molders, and manufacturers.

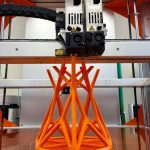

MT’s 4 different FDM 3D printers can accommodate sizes up to 39-inch cubes – even those including moving parts, such as bearings. An SLA printer utilizes resin and a laser to produce more refined detail than the larger printers. Two CNC machines cut and engrave soft metals, wax, and plastics of up to 5-inch cubes. These machines have allowed the company to branch out into electronics. In fact, they will soon be releasing a toy that involves a circuit board designed in-house.

Stearns’ diverse background includes music, automotive business, and manufacturing. Additional experience in sailing and marine retail sparked the idea for his first major creation 12 years ago. That product, a composting toilet, is now distributed worldwide as “Nature’s Head.” It is used in boats, RVs, and tree houses, and is supplied to 45 manufactures of tiny homes. Distributors are located in Europe, Australia, New Zealand, and Canada. In the last 6 months, several components of Nature’s Head have been altered using MT’s 3D printers. Once the design was finalized, a new patent was filed, and the rotational-molded product has gone into production.

In addition to MT and Nature’s Head, Stearns started two factories: one specializes in injection molding, and the other in rotational molding. Before too long, a vacuform company will be added to the family. By then, Stearns’ companies will be able to “take care of virtually any type of plastics manufacturing needs.”

Stearns and his team are open to discussing ideas at any stage of the development process. To get in touch with or learn more about Medal Technologies, visit their website.

Facebook Comments